Sponsored Content by MerckJan 15 2024Reviewed by Emily Magee

Polymers that degrade in a controlled manner are crucial in tissue engineering and drug delivery therapies. A wide range of natural and synthetic biodegradable polymers has been explored for use in medical and pharmaceutical applications.

Image Credit: angellodeco/Shutterstock.com

While natural polymers, including starches and cellulose, are still commonly used in biomedical research, the utilization of synthetic biodegradable polymers in pharmaceutical and tissue-engineering products is growing.

Synthetic polymers offer the advantage of being customizable in their chemical structure. This allows for optimization of the physical properties of biomedical materials. Additionally, they can be produced with higher purity and more precise compositions compared to natural polymers.

There are several chemical classes of synthetic biodegradable polymers that provide good biocompatibility and may be employed to tune the rates of mechanical strength and biodegradation.1

Poly(lactic acid) (PLA), Poly(glycolic acid) (PGA), and their copolymers have been investigated for a wider variety of applications than any other type of biodegradable polymers.

PGA and PLA are both biodegradable polyesters that can degrade in the body via the simple hydrolysis of the ester backbone to non-toxic, non-harmful compounds. The products of degradation are excreted by the kidneys or removed as water and carbon dioxide via biochemical pathways.

The applications of these polymers currently include resorbable implants and surgical sutures, and there is considerable interest in expanding the use of these materials to applications such as drug encapsulation and delivery.

Since PGA/PLA polymers are biocompatible, safe, and non-toxic according to the regulatory agencies in practically all developed countries, the additional applications of these materials can reach the market sooner and are more economical than those that use novel polymers with unproven biocompatibility.

This article presents the properties of the RESOMER® polymers supplied by Merck Millipore Sigma and manufactured by Evonik Röhm Pharma GmbH.

Table 1 details the available RESOMER® products. RESOMER® polymers from Merck Millipore Sigma are only available for research and development applications. Chemically identical GMP materials may be acquired directly from Evonik Röhm GmbH.

Click here to view the list of RESOMER polymers

PGA/PLA properties

The following classes of RESOMER polymers are supplied by Merck:

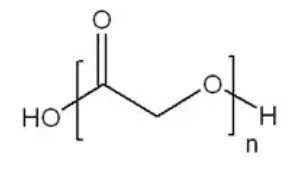

Figure 1. General Structure of PGA. Image Credit: Merck

Poly(glycolic acid) (PGA)

PGA is a highly crystalline material that has a high melting point of 225-230 °C. It also has variable solubility in organic solvents that is usually low, dependent on the molecular weight of the polymer. PGA is susceptible to hydrolysis because of the ester bond in the polymer backbone.

Despite its low solubility, this polymer has been fabricated into a range of structures and forms. The methods employed to develop PGA-based structures include injection, extrusion, and compression molding, in addition to solvent casting and particulate leaching.

Fibers of PGA have a high modulus (7 GPa) and strength and are particularly rigid.2 This has encouraged the study of their use in bone internal fixation devices. However, PGA materials’ brittle nature and low solubility can hinder their functionality in some applications.

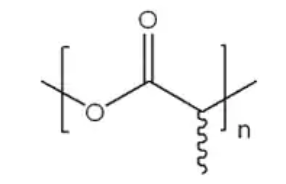

Figure 2. General Structure of PLA. Image Credit: Merck

Poly(lactic acid) (PLA)

Lactide is a chiral molecule with two distinct optically active forms: D-lactide and L-lactide. When each of these monomers is polymerized, it produces a semi-crystalline polymer.

Poly-D,L-lactide (PDLLA) is created by polymerizing a racemic mixture of L- and D-lactides. This results in an amorphous polymer with a glass transition temperature between 55-60 °C. The crystallinity level of PDLLA can be adjusted by varying the ratio of D to L enantiomers in the polymer.

The choice of stereochemistry in PLA (polylactic acid) greatly influences its properties, how it can be processed, and its rate of biodegradation.

Poly (L-lactide), or PLLA, is commonly chosen for cast or extruded biomedical devices. This is because it degrades into L(+)-lactic acid, the naturally occurring stereoisomer. This results in minimal toxicity as it can be easily excreted from the body.3

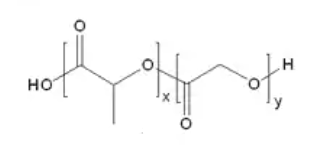

Figure 3. General Structure of PLA: PGA copolymer. Image Credit: Merck

Poly (Lactide-co-Glycolide) Copolymers (PLGA)

Among the co-polyesters investigated, extensive research has focused on developing a full range of PLGA polymers. Both L- and DL-lactides have been used for co-polymerization. The ratio of lactide to glycolide at various compositions enables the degree of crystallinity of the polymers to be controlled.4

Copolymerizing the crystalline PGA with PLA reduces the degree of crystallinity, leading to increases in rates of hydration and hydrolysis. This means that the copolymer’s degradation time is related to the ratio of the monomers used in synthesis.

Generally, the greater the glycolide content, the faster the degradation rate. However, there is an exception to this rule, namely the 50:50 ratio of PGA: PLA, which displays the quickest degradation.5,6

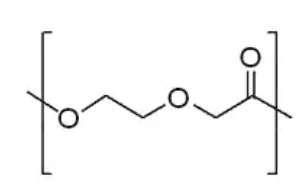

Figure 4. General Structure of Polydioxanone. Image Credit: Merck

Polydioxanone (PDS)

Research is shifting towards developing materials for monofilament sutures, even though biodegradable glycolides and polylactides have traditionally been used for versatile, resorbable multi-filament structures.

This shift is motivated by the fact that multi-filament sutures tend to have a higher infection risk and cause more friction during tissue penetration.7,8

Polydioxanone (PDS) is created through the ring-opening polymerization of the p-dioxanone monomer. It is characterized by a glass transition temperature ranging from -10 °C to 0 °C and has a crystallinity level of about 55%.

The ether oxygen in its chain’s backbone enhances this polymer’s flexibility. In vivo, PDS degrades into low-toxicity monomers and exhibits a lower modulus than PGA or PLA.

For suture production, PDS is extruded into fibers at the lowest possible temperature, a crucial step to prevent spontaneous depolymerization back to the monomer.

End groups

The RESOMER® materials listed in Merck’s catalog are available with three end-group functions: a free carboxylic acid group, an ester terminated group, and an alkyl ester group.

Typically, polymers that are capped with alkyl ester and ester terminated groups have longer degradation lifetimes than the free carboxylic analogs.9 This choice in end group offers a range of PGA/PLA materials with distinctive properties to meet almost any unique research needs.

Quality and specifications of RESOMER polymers

All RESOMER® polymers are manufactured by Evonik Röhm GmbH and conform to a strict set of pre-determined specifications to guarantee that the material has consistent properties for the entire process, from research to commercialization.

Examples of specifications that you may find useful include inherent viscosity, residual monomers, sulfated ash content, and heavy metal content.

In addition to the new RESOMER® products, Merck Millipore Sigma offers a wide range of synthetic biodegradable and natural polymers.

References

- Ratner B, Hoffman A, Schoen F, Lemons J. 2004. Biomaterials Science. 2. London: Elsevier.

- Middleton J, Tipton A. 1998. Medical Plastic and Biomaterials . 30.

- Athanasiou K. 1996. Sterilization, toxicity, biocompatibility and clinical applications of polylactic acid/ polyglycolic acid copolymers. Biomaterials. 17(2):93-102. https://doi.org/10.1016/0142-9612(96)85754-1

- Cohn D, Younes H, Marom G. 1987. Amorphous and crystalline morphologies in glycolic acid and lactic acid polymers. Polymer. 28(12):2018-2022. https://doi.org/10.1016/0032-3861(87)90035-8

- Park TG, Lu W, Crotts G. 1995. Importance of in vitro experimental conditions on protein release kinetics, stability and polymer degradation in protein encapsulated poly (d,l-lactic acid-co-glycolic acid) microspheres. Journal of Controlled Release. 33(2):211-222. https://doi.org/10.1016/0168-3659(94)00084-8

- Miller RA, Brady JM, Cutright DE. 1977. Degradation rates of oral resorbable implants (polylactates and polyglycolates): Rate modification with changes in PLA/PGA copolymer ratios. J. Biomed. Mater. Res.. 11(5):711-719. https://doi.org/10.1002/jbm.820110507

- Krukowski ZH, Cusick EL, Engeset J, Matheson NA. 1987. Polydioxanone or polypropylene for closure of midline abdominal incisions: A prospective comparative clinical trial. Br. J. Surg.. 74(9):828-830. https://doi.org/10.1002/bjs.1800740927

- Schoetz DJ. 1988. Closure of Abdominal Wounds With Polydioxanone. Arch Surg. 123(1):72. https://doi.org/10.1001/archsurg.1988.01400250082015

- Houchin M, Topp E. 2008. Chemical Degradation of Peptides and Proteins in PLGA: A Review of Reactions and Mechanisms. Journal of Pharmaceutical Sciences. 97(7):2395-2404. https://doi.org/10.1002/jps.21176

About Merck

Our pursuit is progress for people everywhere. That's why we take a closer look at things, ask questions, and think ahead.

We've been around for more than 350 years, yet our majority owners are still the descendants of Friedrich Jacob Merck, the man who founded our company in Darmstadt, Germany in 1668.

From advancing gene-editing technologies and discovering unique ways to treat the most challenging diseases to enabling the intelligence of devices – the company is everywhere.

We are Merck. The only exceptions are the United States and Canada. Here we operate as EMD Serono in the Biopharma business, as MilliporeSigma in the Life Science business, and as EMD Performance Materials in the materials business.

Our life science business

We provide infinite solutions to solve the toughest problems in life science in collaboration with the global scientific community. Our tools, services, and digital platforms empower scientists and engineers at every stage, helping deliver breakthrough therapies more quickly.

Focus areas

With our three business units, we are a leading worldwide supplier of tools, high-grade chemicals, and equipment for academic labs, biotech, and biopharmaceutical manufacturers, as well as the industrial sector.

- Research Solutions provides our academic customers with the chemicals and tools needed to make scientific discovery easier and faster.

- Process Solutions provides drug manufacturers with process development expertise and technologies, such as continuous bioprocessing.

- Applied Solutions offers both testing kits and services to ensure that our food is safe to eat and our water is clean to drink.

Sponsored Content Policy: News-Medical.net publishes articles and related content that may be derived from sources where we have existing commercial relationships, provided such content adds value to the core editorial ethos of News-Medical.Net which is to educate and inform site visitors interested in medical research, science, medical devices and treatments.